Corona Treatment Expertise for Converting and Extruding Film

CORONA PROCESS

Corona treaters which are used in plastic sector over 45 years, make electron bombardment on polymer surfaces. So, corona treaters are also called bombardment equipment.

| Components processed: • Conductive & non-conductive narrow webs • Electrical cables • Pipes & Tubes • Medical devices • Automotive components • Board & Foam • 3D parts • Extruded profiles • Domestic appliances And many more.. |

Modification prior to: • Bonding/Gluing • Coating • Laminating • Labeling • Painting • Flocking • Printing • Sealing • Over moulding • Gasketing And many more... |

| Industries served • Automotive • Manufacturing • Injection moulding • Extrusion • Electrical • Medical device manufacture • Research establishments • Universities • R&D Departments / Test labs • And many more.... |

Materials processed • PP • PEEK • PA • TPE • PC • PE, HDPE • Composites • Acrylics • Films • And many more... |

a) Purpose of Corona Treatment

The purpose of corona treating is to improve the wettability and adhesion characteristics of plastic substrates to inks and adhesives. Unlike the purely mechanical bond, as in the case of an ink penetrating into a porous surface like paper, plastic films will generally need some means of surface treatment to achieve acceptable chemical bonding with the ink or adhesive.

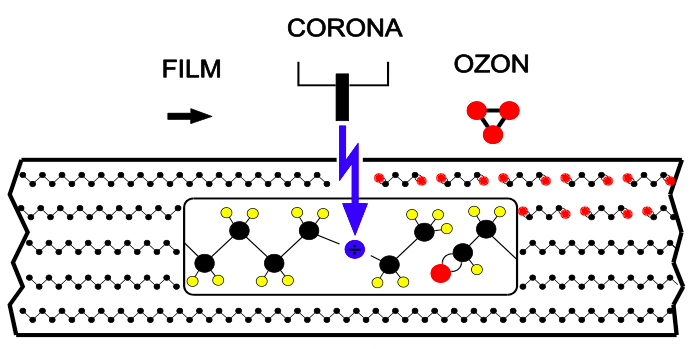

b)Theory of Corona Treatment

Although there are numerous theories explaining the principles behind the process of corona treating, the most commonly accepted theory appears to be the theory of high speed oxidation. Basically, this theory states that the energy of the corona breaks the molecular bonds on the surface of the non-polar substrate. The broken bonds then recombine with the free radicals in the corona environment to form additional polar groups on the film surface. These polar groups have a strong chemical affinity to the polar inks and adhesives, which results in improved adhesion. Similarly, the polar surface results in an increased surface energy which correlates with improved wettability.

c) Components of Corona Treating Systems

All corona treatment systems have two components. The first component is the power source and the second component is the treater station.

Power Source

The power source generally consists of a high frequency generator and a high voltage output transformer. In very general terms, the purpose of the power source is to raise the incoming electricity (typically 50/60 Hz, 230/400 V) to a higher frequency and higher voltage. The power source is commonly referred to as a power supply or a generator. Typically, power supplies are rated in kilowatts (kW) and can range from 1kW to 20 kW, depending on the application.

Treater Station

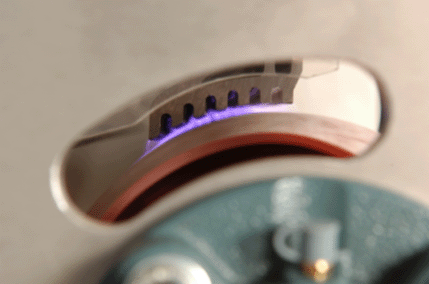

Station is place of corona treatment of films.There can be made different designs according to material which will be treated. All treater stations have a high voltage electrode and a ground electrode. A solid dielectric (insulating) material is needed to cover one of the two electrodes in order to generate a corona atmosphere, as opposed to a "lightening bolt" charge.

Spare Parts !!!